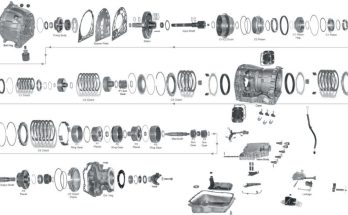

The 1000 series Allison was specifically designed for heavy duty in commercial trucks. The Allison 1000 comes in either a 5 or 6-speed unit and are manufactured by Allison Transmission in Indianapolis, Indiana as well as in Baltimore, Maryland and in Erskine, Minnesota.

The 1000 series is the smallest transmission that Allison manufactures, but don’t that make you think it can’t handle abuse. The Allison 100 is an extremely capable transmission and is highly used in Duramax powered GM trucks and even busses.

Looking to find a new or used Allison 1000 transmission or parts for your car, truck or SUV?

Get The Best Prices on New or Used Allison 1000 Transmissions & Parts

Allison 1000 Transmission Information

- What Vehicles Were The Allison 1000 Found In?

- Allison Specs

- Allison 100 Transmission Maintenance

- Allison 1000 Upgrades

- Allison 1000 Problems

What Vehicles Did The Allison 1000 Come In?

- Chevrolet Silverado

- Chevrolet Kodiak

- GMC Sierra

- GMC Topkick

- Hummer H1

- Chevrolet B-Series bus

Allison 1000 Transmission Specs

Case Material: Aluminum

Horsepower Rating: 350-400 hp (in stock 5-speed trim) / 425-450 hp (In stock 6-speed trim)

Torque Rating: 620 ft lbs (5-speed) / 765 ft bls (2011+)

Weight: 330 pounds (Dry)

Fluid Capacity: 12.7 Quarts

Gear Ratios:

- 1st Gear: 3.10:1

- 2nd Gear: 1.81:1

- 3rd Gear: 1.41:1

- 4th Gear: 1.00:1

- 5th Gear: 0.71:1

- 6th gear: 0.61:1 (2006+)

- Reverse: 4.49:1

Allison 1000 Transmission Fluid Type & Specs

What Type of Transmission Fluid Does An Allison 1000 Use?

The Allison 1000 can use Dexron 3 (recommended by GM), Dexron 6 (recommended by GM) or TranSynd (recommended by Allison.

This makes transmission fluid changes easy since you can get whatever fluid you need easily if using a Dexron 3 or 6.

How Many Quarts of Transmission Fluid Does an Allison 1000 Take?

The Allison 1000 takes Dexron 3 (Dex III), Dexron 6 (Dex VI), or TranSynd (preferred) transmission fluid and has a 11 – 13 quart dry fill capacity including torque converter. When dropping the transmission pan to perform a standard drain and fill transmission fluid change, you can expect to replace around 7.5 quarts of fluid assuming the stock transmission pan is being used.

If you have a deeper aftermarket transmission pan on your Allison 1000 transmission, then this quart estimate will likely be more and require you to check fluid levels as you fill and run the transmission through the gears.

- Delivers improved gear protection.

- Delivers extended anti-shudder durability.

- Delivers extended clutch-friction durability.

- Excellent corrosion and foaming resistance.

- Excellent thermal and oxidative stability that helps to prevent deposits and oil thickening.

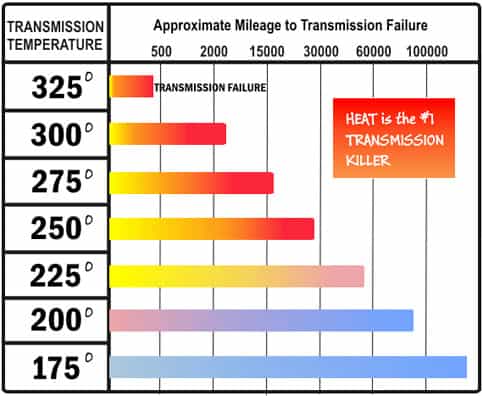

Allison Transmission Fluid Temperature

The ideal operating temperature of the Allison 1000 is in the 160-200 range when fully warmed up. Due to the nature of the Allison 1000, and the load it often sees based on being a heavy duty use transmission, transmission temps can easily reach 200+, especially when towing or hauling at low speeds of sitting in traffic.

While 200 degrees isn’t the ideal, it’s not the end of the world. The Allison 1000 was designed for extreme use, so it is engineered to withstand higher than average heat. Although it can handle it, it’s always best to keep transmission temps down, and add a transmission cooler where necessary.

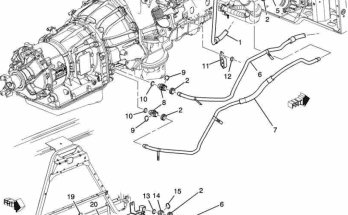

Allison 1000 Transmission Filter

Transmission filter kits for the Allison 1000 are simple, however, the Allison 1000 has 2 filters, one that a standard internal filter like most transmissions, and a secondary external spin on style filter similar to what you have on an engine.

Allison 1000 transmission filters can come on their own with just the external filter, or as a complete kits which includes a new pan gasket, internal filter with filter seal, and external filter which will cost around $20 – $200 (which includes deep pan and extras. The filters we recommend for your Allison 1000 are:

- PPE 128059150 (external filter only – larger filter)

- Deep filter with spin on and pan gasket kit

- Genuine Allison 1000 Deep Pan Kit

Allison 1000 Transmission Maintenance

The Allison 1000 requires recommended maintenance of changing the fluid, and filter every 30,000 – 50,000 miles depending on usage. If you have a truck that you use to tow or haul often, it’s best to check your fluid and make a determination as to how frequent you should change out your fluid.

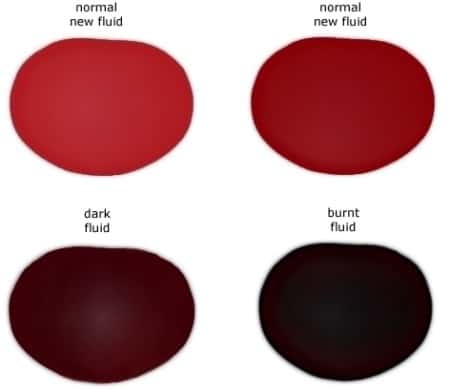

When checking your transmission fluid, be sure to not only look at the fluid level, but the color and smell. Good transmission fluid will have a reddish color to it, but if it looks dark, almost brown and has a slight burnt smell to it, then you are very past due on your maintenance. The chart below shows how transmission fluid looks at various stages.

Allison 1000 Transmission Fluid Change

Changing transmission fluid in your Allison 1000 is not an overly complicated process and is recommended every 30,000 for most use cases

Doing a transmission fluid and filter change on an Allison 1000 is rather straight forward and can be done by the average DIY weekend mechanic.

Below is a detailed video of performing a transmission fluid change on an Allison 1000 in a GMC Sierra.

How many quarts does it take to do a fluid and filter change on an Allison 1000 trans?

For a typical pan drop and fluid change, you will need about 7.5-10 quarts to do the job depending on if you have a factory pan or aftermarket deep pan.

As always, start with adding a few quarts of atf when you have the new filter and pan back on and shift through the gears to get fluid moving and warm, then keep checking and added until you have the right level.

Allison 1000 Upgrades

When it comes to upgrading your Allison 1000, besides adding better internals and hard parts, there are a few simple upgrades that you can make to keep transmission temps down. The most common simple DIY Allison 1000 upgrades that can be done with simple hand tools in your driveway without removing the transmission to tear apart are definitely transmission coolers, pans, and thermostat bypass.

Allison 1000 Common Problems & Weaknesses

The Allison 1000 transmission is a workhorse, and is extremely reliable in nearly all applications. The transmission was designed for heavy duty use and with routine maintenance, is typically trouble free.

Like all transmissions, no matter how reliable they are, there are always some commonly known problems. In the case of the Allision 1000, the most common problems and weaknesses include:

- Adaptive Learning

- C3 Clutch Lubrication

- C1 & C2 Clutch Wear

Adaptive Learning

Allison 1000 transmissions utilize adaptive learning, which compares key shift parameters to pre-programmed (and the most ideal) shift conditions and engine’s torque values on a consistent basis.

The Allison 1000’s adaptive learning compares its average shift time against the preprogrammed ideal benchmarks. This process allows the Allison 1000 to “adapt” and make shifting more efficient.

The issue with this though is that any rapid changes in speed or sporadic acceleration or deceleration prevent this process from occurring and the gear and valve assemblies cannot adapt to fluid pressure increases.

An example of this is going from stop and go city driving to aggressive drag race scenarios. Sudden and extreme changes do not give the electronics enough time to react fast enough for the required harder and faster shifts needed under such situations.

C3 Clutch Issues

In addition to the adaptive learning problems, another well known problem is that the Allison 1000’s C3 clutch suffers from a lack of lubrication.

Based on how the Allison 1000 is designed, the C3 clutch does not get any fluid unless it’s done directly. This reduces performance due to wear on the clutch pad which can ultimately lead to complete transmission failure.

C1 & C2 Clutch Issues (5-Speed Allision 1000 Only)

5-speed Allison 1000 transmissions have common problems with the C1 and C2 clutches. The apply pistons that allow for clutch engagement were designed off-center. This creates an issue of uneven pressure applied to the clutches, which ultimately leads to uneven wear and potential for premature C1 and C2 clutch failure.